Welcome to AC Systems Level 1 Lesson 3, where we delve into the intricate world of heating, ventilation, and air conditioning (HVAC) systems. This lesson will equip you with a comprehensive understanding of the components, functions, troubleshooting techniques, maintenance procedures, and safety precautions associated with AC systems.

As we navigate through this lesson, we will explore the refrigerant cycle, identify common AC system problems and their solutions, and emphasize the importance of regular maintenance to ensure optimal performance and longevity.

HVAC System Overview

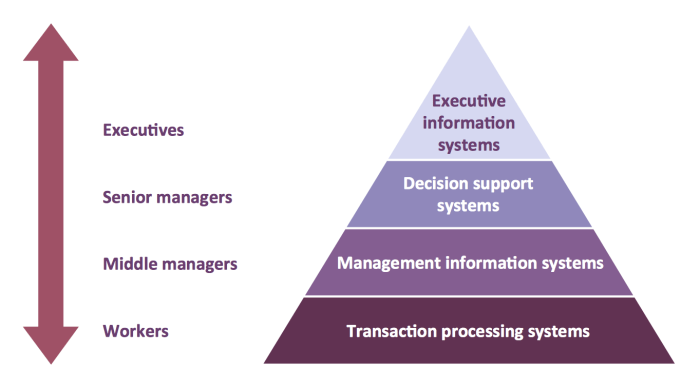

An HVAC system, short for heating, ventilation, and air conditioning, is designed to regulate the temperature and air quality within a building or confined space. In this lesson, we will focus on the AC (air conditioning) component of an HVAC system, which is responsible for cooling and dehumidifying the air.An

AC system consists of several key components, each with its specific function:

- Condenser:Located outdoors, the condenser releases heat from the refrigerant into the surrounding air.

- Evaporator:Installed indoors, the evaporator absorbs heat from the air inside the building.

- Compressor:The compressor circulates the refrigerant through the system, compressing it and increasing its pressure.

- Expansion valve:The expansion valve controls the flow of refrigerant into the evaporator.

- Refrigerant:A specialized fluid that absorbs and releases heat as it circulates through the system.

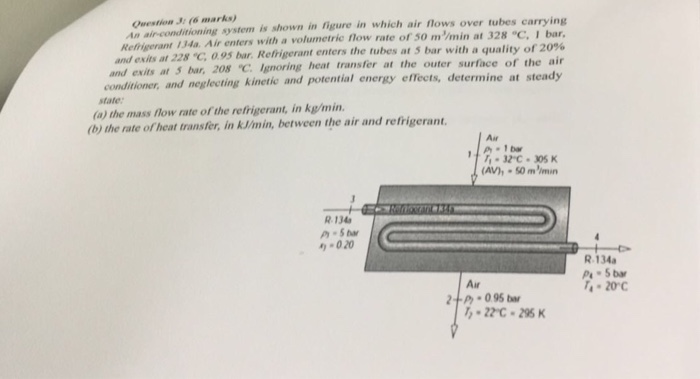

The AC system operates on the principle of the refrigerant cycle, which involves four main steps:

- Compression:The compressor compresses the refrigerant gas, increasing its pressure and temperature.

- Condensation:The hot, high-pressure refrigerant gas flows into the condenser, where it releases heat to the outside air and condenses into a liquid.

- Expansion:The liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature, causing it to expand and vaporize.

- Evaporation:The low-pressure, cold refrigerant vapor enters the evaporator, where it absorbs heat from the indoor air and evaporates into a gas.

By continuously circulating the refrigerant through this cycle, the AC system removes heat and moisture from the indoor air, providing a cooler and more comfortable environment.

AC System Troubleshooting

Maintaining a comfortable indoor environment during hot weather is essential, and an efficient AC system plays a crucial role in achieving this. However, even the most well-maintained systems can encounter occasional problems that affect their performance. Troubleshooting these issues promptly is important to ensure continued comfort and prevent more severe problems.

Common AC System Problems

Identifying the underlying cause of an AC system issue is essential for effective troubleshooting. Here are some common problems, along with their causes and symptoms:

- Inadequate Cooling:This can be caused by insufficient refrigerant, clogged air filters, dirty coils, or a malfunctioning compressor.

- Excessive Noise:Unusual noises, such as rattling, squealing, or humming, can indicate loose parts, worn bearings, or a refrigerant leak.

- High Energy Consumption:An inefficient AC system can lead to higher energy bills. This can be caused by dirty coils, clogged air filters, or a malfunctioning thermostat.

- Short Cycling:Frequent on-and-off cycles can indicate a refrigerant leak, dirty coils, or a faulty thermostat.

- Frozen Evaporator Coil:A build-up of ice on the evaporator coil can restrict airflow and reduce cooling efficiency. This can be caused by low refrigerant levels, dirty coils, or a malfunctioning fan.

Troubleshooting Steps

Once the potential cause of an AC system problem has been identified, troubleshooting steps can be taken to resolve the issue:

- Check Refrigerant Levels:Use a refrigerant gauge to measure the pressure in the system and identify any leaks or insufficient levels.

- Clean Air Filters:Replace or clean dirty air filters to ensure proper airflow.

- Clean Coils:Use a coil cleaner to remove dirt and debris from the evaporator and condenser coils.

- Inspect Electrical Components:Check for loose connections, damaged wires, or malfunctioning components, such as the compressor or thermostat.

- Inspect Ductwork:Ensure that there are no leaks or blockages in the ductwork that could restrict airflow.

AC System Maintenance

Regular AC system maintenance is crucial for optimal performance, energy efficiency, and longevity. By proactively addressing potential issues, you can prevent costly repairs and extend the lifespan of your system.

After delving into the intricacies of AC systems in Level 1 Lesson 3, it’s time to shift gears and tackle the complexities of wine with a WSET Level 3 practice exam . Don’t worry, though; the knowledge you’ve gained in Lesson 3 will serve you well as you navigate the nuances of wine production, tasting, and evaluation.

Let’s dive back into the world of AC systems, armed with a newfound appreciation for the art of winemaking.

Routine Maintenance Checkup

A routine maintenance checkup typically involves:

- Inspecting and cleaning the condenser coils to remove dirt and debris.

- Checking refrigerant levels and adjusting as needed.

- Lubricating moving parts to minimize friction and wear.

- Inspecting and cleaning the evaporator coils.

- Checking the electrical connections for any loose or damaged wires.

Maintenance Schedule

For optimal performance, it’s recommended to schedule AC system maintenance at least once a year, preferably before the peak cooling season. In areas with heavy usage or extreme weather conditions, more frequent maintenance may be necessary. By adhering to a regular maintenance schedule, you can ensure your AC system operates efficiently and reliably throughout its lifespan.

AC System Installation: Ac Systems Level 1 Lesson 3

Installing an AC system requires meticulous planning and execution. The process typically involves several steps to ensure optimal performance and longevity of the system.

Site Assessment and Design

A thorough site assessment is crucial to determine the appropriate location and size of the AC system. Factors to consider include the building’s layout, insulation, sun exposure, and local climate conditions. Based on this assessment, an HVAC professional designs a system that meets the specific cooling needs of the space.

Equipment Selection

Choosing the right AC system depends on various factors, including the size of the space, the desired level of cooling, and the energy efficiency requirements. Different types of AC systems available include:

- Split systems: Consists of an outdoor condenser unit and an indoor evaporator unit connected by refrigerant lines.

- Packaged systems: Combines all components into a single outdoor unit, making installation simpler.

- Central systems: Uses a central air handler and ductwork to distribute conditioned air throughout the building.

Installation Process

The installation process typically involves:

- Installing the outdoor unit on a stable base or platform.

- Connecting the refrigerant lines between the indoor and outdoor units.

- Mounting the indoor unit on a wall or ceiling.

- Connecting the electrical wiring and controls.

- Charging the system with refrigerant.

- Testing and commissioning the system to ensure proper operation.

AC System Safety

Working on AC systems requires adhering to strict safety precautions due to the potential hazards they pose. Understanding these hazards and implementing preventive measures is crucial to avoid accidents and ensure a safe working environment.

Electrical hazards are prominent in AC systems, as they operate on high voltages. Contact with live wires or components can result in electrical shock, burns, or even electrocution. Additionally, refrigerant gases used in AC systems can be toxic and pose inhalation risks.

Refrigerant leaks can also lead to frostbite or chemical burns if not handled properly.

Preventing Accidents, Ac systems level 1 lesson 3

- Wear appropriate safety gear:Always wear insulated gloves, safety glasses, and non-conductive footwear when working on AC systems.

- De-energize the system:Before performing any maintenance or repairs, ensure the AC system is completely de-energized by turning off the power supply.

- Use proper tools:Employ insulated tools specifically designed for electrical work to prevent electrical shock.

- Handle refrigerants safely:Wear a respirator when handling refrigerants and ensure proper ventilation to avoid inhalation risks.

- Inspect regularly:Regularly inspect AC systems for any signs of damage, leaks, or loose connections to identify potential hazards.

Query Resolution

What are the most common AC system problems?

Common AC system problems include refrigerant leaks, clogged filters, dirty coils, and electrical issues.

How often should I have my AC system maintained?

It is recommended to have your AC system inspected and maintained at least once a year, preferably before the start of the cooling season.

What safety precautions should I take when working on AC systems?

When working on AC systems, it is essential to wear protective gear, ensure proper ventilation, and avoid contact with electrical components.