Welcome to our comprehensive guide on Section 2 Reinforcement Types of Bonds Answer Key, where we delve into the intricate world of reinforcement bonds, exploring their diverse characteristics, applications, and the advantages and disadvantages associated with each type. Get ready to enhance your understanding of this crucial aspect of construction engineering.

In this guide, we will thoroughly examine structural, mechanical, and chemical reinforcement bonds, providing you with a deep understanding of their roles in reinforcing concrete structures and improving their overall performance. Let’s dive right in!

Section 2 Reinforcement Types of Bonds Answer Key

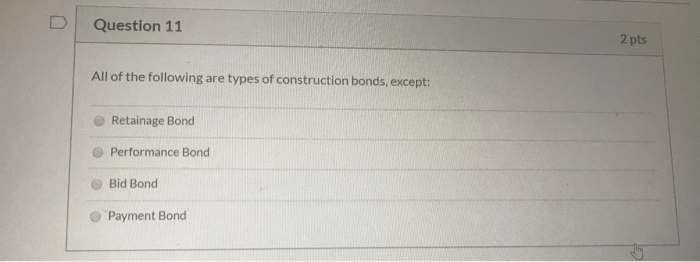

Reinforcement bonds play a crucial role in strengthening and enhancing the durability of concrete structures. Understanding the different types of reinforcement bonds and their characteristics is essential for effective structural design and construction.

Types of Reinforcement Bonds

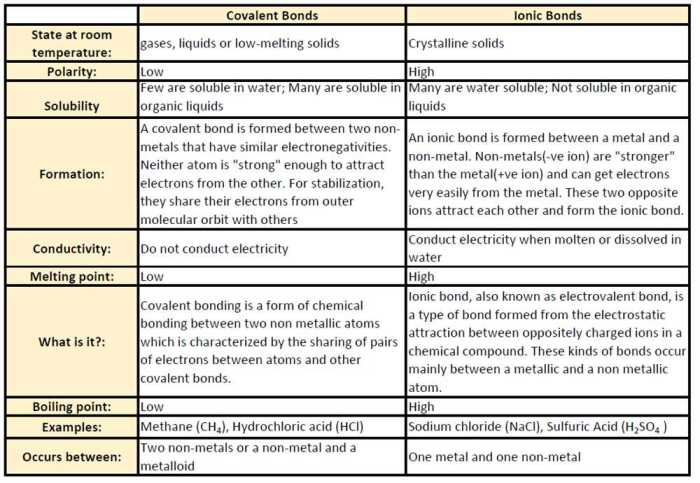

- Chemical Bond:Forms through the hydration reaction between cement and water, creating a strong bond between the reinforcement and the concrete.

- Mechanical Bond:Created through the interlocking action of deformations or ribs on the reinforcement with the surrounding concrete.

- Frictional Bond:Results from the friction between the reinforcement and the concrete, providing resistance to pull-out.

- Adhesion Bond:Involves the bonding of the reinforcement to the concrete through the formation of a thin layer of cement paste.

The type of reinforcement bond used depends on the specific requirements of the structure and the desired performance characteristics.

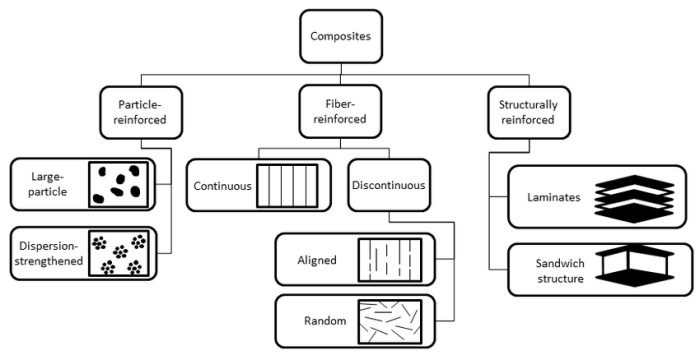

Structural Reinforcement

Structural reinforcement aims to enhance the strength and stability of concrete structures. It involves the use of materials such as steel bars, rebars, or meshes to resist tensile forces and prevent cracking.

Materials for Structural Reinforcement:

- Steel:Widely used due to its high strength, durability, and bondability with concrete.

- Fiber-Reinforced Polymers (FRPs):Offer high tensile strength and corrosion resistance, but can be more expensive than steel.

- Glass Fiber-Reinforced Concrete (GFRC):Provides high flexural strength and is lightweight, making it suitable for precast applications.

Mechanical Reinforcement

Mechanical reinforcement systems employ external or internal devices to provide additional strength and support to concrete structures.

Types of Mechanical Reinforcement Systems:

- Post-Tensioning:Uses high-strength steel cables or bars tensioned after the concrete has cured, inducing a compressive force.

- External Reinforcement:Attaches steel plates, fiber-reinforced polymers, or other materials to the concrete surface to increase its strength.

- Anchors:Connect reinforcement to the concrete and transfer loads between different structural elements.

Chemical Reinforcement, Section 2 reinforcement types of bonds answer key

Chemical reinforcement involves the addition of chemical agents to concrete to improve its properties and durability.

Types of Chemical Reinforcement Agents:

- Admixtures:Enhance the workability, strength, and durability of concrete by altering its chemical composition.

- Corrosion Inhibitors:Protect reinforcement from corrosion by forming a protective layer on its surface.

- Superplasticizers:Reduce the water content in concrete without compromising its workability, leading to higher strength and durability.

Common Queries

What are the key differences between structural, mechanical, and chemical reinforcement bonds?

Structural reinforcement bonds enhance the tensile strength of concrete, mechanical reinforcement bonds provide additional support through external systems, and chemical reinforcement bonds improve the internal properties of concrete.

When is it appropriate to use mechanical reinforcement?

Mechanical reinforcement is ideal when additional strength is required beyond what structural reinforcement can provide, such as in areas subjected to high loads or seismic activity.

What are the advantages of chemical reinforcement?

Chemical reinforcement improves the durability, water resistance, and overall performance of concrete, making it suitable for structures exposed to harsh environments.