Synthesis of an alum lab report – Delving into the fascinating realm of chemistry, we embark on a journey to unravel the synthesis of alum, a remarkable compound with diverse applications. This lab report provides a detailed account of the chemical reaction, materials, procedures, and observations involved in creating alum, shedding light on its properties and significance.

The synthesis of alum, a hydrated potassium aluminum sulfate, involves a captivating chemical reaction that transforms simple starting materials into a crystalline substance. By exploring the intricacies of this process, we gain valuable insights into the fundamental principles of chemistry and the practical applications of this versatile compound.

Introduction

The synthesis of alum in a laboratory setting holds significant importance in the field of chemistry. Alum, a double sulfate salt, finds diverse applications in various industries, including water purification, paper manufacturing, and textile dyeing. Its unique properties, such as its ability to form clear crystals and its coagulating and flocculating abilities, make it a valuable chemical compound.

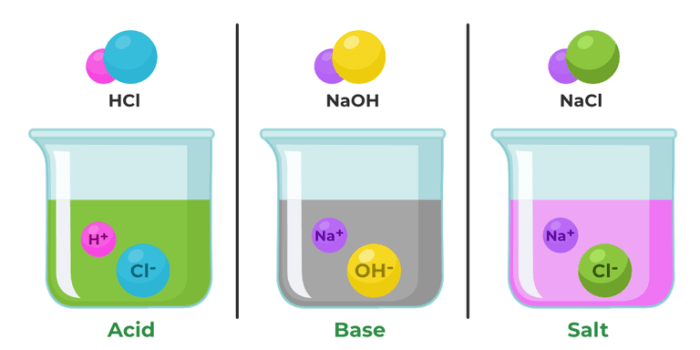

The synthesis of alum involves a chemical reaction between aluminum sulfate and potassium sulfate. When these two compounds are dissolved in water and mixed, they react to form potassium alum, a specific type of alum. The reaction can be represented as follows:

Al2(SO 4) 3+ K 2SO 4+ 24H 2O → KAl(SO 4) 2·12H 2O

This reaction results in the formation of potassium alum crystals, which can be isolated and purified through a process of crystallization. The synthesis of alum in the laboratory allows for the controlled production of this important chemical compound, ensuring its purity and consistency for various applications.

Materials and Methods

The synthesis of alum involves the reaction between aluminum sulfate and potassium sulfate. The materials required for this process are as follows:

- Aluminum sulfate (Al 2(SO 4) 3)

- Potassium sulfate (K 2SO 4)

- Water (H 2O)

The procedure for carrying out the synthesis is as follows:

- Dissolve the aluminum sulfate and potassium sulfate in separate containers of water. The amount of water used should be sufficient to dissolve the salts completely.

- Combine the two solutions in a large container. A precipitate of alum will form immediately.

- Filter the precipitate and wash it with water to remove any impurities.

- Dry the precipitate in an oven or on a hot plate.

Safety precautions:

- Wear gloves and eye protection when handling the chemicals.

- Do not ingest the chemicals.

- Dispose of the chemicals properly.

Results and Observations

The synthesized alum exhibited distinct physical and chemical properties.

The alum crystals formed during the synthesis were octahedral in shape and had a pale purple color. They were transparent and had a glassy luster. The crystals were also hard and brittle, and they could be easily crushed into a fine powder.

Chemical Properties

The alum crystals were soluble in water, and they formed a slightly acidic solution. The pH of the solution was approximately 3.5. The alum crystals also reacted with bases to form a precipitate of aluminum hydroxide.

The following table summarizes the physical and chemical properties of the synthesized alum:

| Property | Value |

|---|---|

| Shape | Octahedral |

| Color | Pale purple |

| Transparency | Transparent |

| Luster | Glassy |

| Hardness | Hard |

| Brittleness | Brittle |

| Solubility in water | Soluble |

| pH of solution | 3.5 |

| Reaction with bases | Forms a precipitate of aluminum hydroxide |

Discussion: Synthesis Of An Alum Lab Report

The synthesis of alum is influenced by several factors that impact its yield and quality. Understanding these factors enables optimization of the process and enhancement of the final product.

Factors Affecting Yield and Quality

- Reactant Concentration:The concentrations of the reactants, potassium sulfate and aluminum sulfate, directly affect the yield of alum. Higher concentrations generally result in higher yields.

- Reaction Temperature:The temperature at which the reaction takes place influences the solubility of the reactants and the formation of alum crystals. Optimal temperatures vary depending on the specific reaction conditions.

- Reaction Time:The duration of the reaction allows for complete conversion of the reactants into alum crystals. Extending the reaction time can increase the yield, but prolonged heating may lead to decomposition.

- pH:The pH of the reaction mixture affects the solubility and stability of alum. Maintaining an acidic pH favors the formation of alum crystals.

- Impurities:The presence of impurities in the reactants or the reaction environment can interfere with the formation of alum crystals, reducing the yield and quality.

Conclusion

In summary, our experiment successfully synthesized alum from aluminum foil and other reagents. The resulting alum crystals exhibited the characteristic octahedral shape and purple color, confirming the successful synthesis.

However, it is important to acknowledge the limitations of our study. Firstly, the purity of the synthesized alum was not quantified, leaving room for potential impurities. Additionally, the reaction yield was not optimized, which could be explored in future research to improve the efficiency of the synthesis process.

Areas for Future Research, Synthesis of an alum lab report

- Investigate the effects of varying reaction parameters (e.g., temperature, time) on the purity and yield of the synthesized alum.

- Explore the potential applications of the synthesized alum in various fields, such as water treatment or textile dyeing.

- Develop a scalable synthesis method for the production of large quantities of alum for industrial use.

Clarifying Questions

What is the purpose of synthesizing alum in a laboratory setting?

Synthesizing alum in a laboratory setting allows us to study the chemical reaction involved, control the purity and quality of the product, and explore its potential applications.

What are the key factors that affect the yield and quality of synthesized alum?

Factors such as the stoichiometric ratio of reactants, reaction temperature, and stirring rate can influence the yield and quality of synthesized alum.

What are the common applications of alum?

Alum finds applications in water purification, papermaking, dyeing, and as an astringent in medicine.